SCOPE OF WORK

ALUMINUM COMPOSITE PANEL

REPORT NUMBER

251014005SHF-001

TEST DATE(S)

2025-10-14 - 2025-10-22

ORIGINAL ISSUE DATE

2025-10-23

PAGES

7

DOCUMENT CONTROL NUMBER

LFT-APAC-SHF-OP-10k(January 13, 2025)© 2025 INTERTEK

Statement

1.This report is invalid without company’s special seal for testing on the assigned page.

2.This report is invalid without an authorized person’s signature.

3.This report is invalid if altered.

4.Only the Client is authorized to permit copying or distribution of this report and then only in its entirety. Don’t copy this report in partial without any official approval in written by our company. This report is invalid without re-stamping the special seal for testing in copying report.

5.This report is for the exclusive use of Intertek's Client and is provided pursuant to the agreement between Intertek and its Client. Intertek's responsibility and liability are limited to the terms and conditions of the agreement. Intertek assumes no liability to any party, other than to the Client in accordance with the agreement, for any loss, expense or damage occasioned by the use of this report. Any use of the Intertek name or one of its marks for the sale or advertisement of the tested material, product or service must first be approved in writing by Intertek. The observations and test results in this report are relevant only to the sample(s) tested. This report by itself does not imply that the material, product, or service is or has ever been under an Intertek certification program.

6.Except for the obligation, responsibility and liability (if any) for the appropriateness and professionality of afore-mentioned testing itself within the scope and amount of the testing fee received, Intertek does not and will not accept any other obligation or liability.

7.If the Client has any questions about the test results, Intertek B&C should be informed within the storage period of the samples. The sample storage period ends 5 working days after the offical report issue date. Samples of certification program are retained for the period required by the certification rules. The samples storage period shall be calculated according to the issue date of the original report in the case of quoting results and modifying reports.

8.Intertek B&C will service this report for the entire test record retention period. The test record retention period ends 6 years after this report original issue date. The test record retention period for certification program is 10 years. Test records and other pertinent project documentation will be retained for the entire test record retention period.

9.The report was digital signed by Shang Hai, Intertek Group plc, please using Adobe Acrobat Reader to verify the authenticity.

Test Report

Original Issue Date: 2025-10-23

Intertek Report No. 251014005SHF-001

Applicant: WENZHOU JIXIANG COMPOSITE PANEL CO., LTD

Address: No.228 Weisan Road , Yueqing Economic Industry zone , Wenzhou City , Zhejiang Province, China. 325600 Attn: Brant Wu

Manufacturer: WENZHOU JIXIANG COMPOSITE PANEL CO., LTD

Address: No.228 Weisan Road , Yueqing Economic Industry zone , Wenzhou City , Zhejiang Province, China.

325600

Test Type:Performance test, samples provided by the applicant.

Product Information

|

Product Name |

Model |

Specification |

Brand |

|

ALUMINUM COMPOSITE PANEL |

A2 FR (FIRE RESISTANT) |

4MM |

ALUSIGNPANEL |

|

Sample ID |

Sample Amount |

Sample Received Date | |

|

S251014005SHF.001~005 |

15 pcs |

2025-09-24, 2025-09-29 | |

| Sample Description | |||

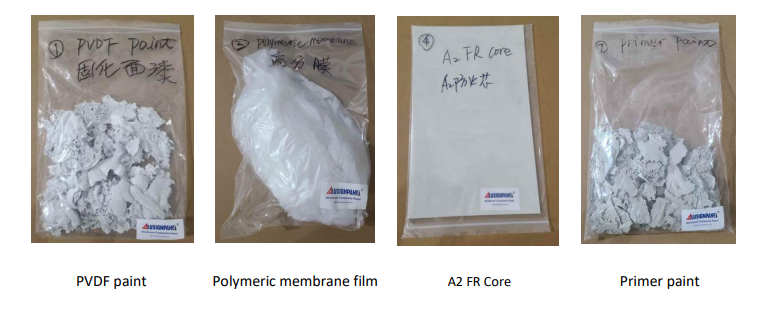

| The sample consists of one package of core material, two packages of adhesive film, two packages of coating and some complete panels with a thickness of about 4mm, see sample photo in Appendix A | |||

Test Methods And Standards

|

Test Standard |

EN 13823:2020+A1:2022 and EN ISO 11925-2:2020 |

|

Specification Standard |

EN 13501-1:2018 |

|

Test Conclusion |

The samples were tested according to the above standards, and the results are shown in the following page. |

Note:

1.This report does not involve sampling. The report only reflects conformity of the tested items of the samples provided by the testing applicant. Representativeness and authenticity of the submitted samples are responsibilities of the testing applicant.

2.The heat of combustion test section in this report only reflects the testing result based on the data and information followed the Δ mark provided by the testing applicant. The testing applicant agrees that Intertek has no duty, responsibility or obligation including without limitation examination, review, analysis, assessment, comment, suggestion, adjustment, calibration, modification, revision, guarantee or otherwise in regard to the legitimacy, compliance, applicability, adequacy, necessity, reasonableness, accuracy, appropriateness, reliability or any other feature or aspect of the data and information.

Original Issue Date: 2025-10-23

Intertek Report No. 251014005SHF-001

Test Items, Method and Results:

The classification was determined in accordance with EN 13501-1:2018. The class A2 with its corresponding fire performance is given in the table below. Table - Class of reaction to fire performance for construction products excluding floorings and linear pipe thermal insulation products. Class Test Method(s) Classification criteria Additional classifications EN 13501-1:2018 Fire classification of construction products and building elements - Part 1: Classification using data from reaction to fire tests

1.1 HEAT OF COMBUSTION TEST

The test was conducted in accordance with EN ISO 1716. This test evaluates the gross heat of combustion (QPCS) of products at constant volume in a bomb calorimeter.

1.2 SINGLE BURNING ITEM TEST

The test was conducted in accordance with EN 13823. This test evaluates the potential contribution of a product to the development of a fire, under a fire situation simulating a single burning item near to the product.

1.3 CLASSIFICATION CRITERIA

The classification was determined in accordance with EN 13501-1:2018. The class A2 with its corresponding fire performance is given in the table below.

Table - Class of reaction to fire performance for construction products excluding floorings and linear pipe thermal insulation products.

|

Class |

Test Method(s) |

Classification criteria |

Additional classifications |

|

A2 |

EN ISO 1716 and |

PCS ≤3.0 MJ/kgaand

PCS ≤4.0 MJ/m2band PCS ≤4.0 MJ/m2cand

PCS ≤3.0 MJ/kgd

|

-- |

|

EN 13823 |

FIGRA0.2MJ≤ 120 W/s and LFS < edge of specimen and THR600s≤ 7.5 MJ |

Smoke productioneand Flaming droplets/particlesf |

Note:

a. For homogeneous products and substantial components of non-homogeneous products.

b. For any external non-substantial component of non-homogeneous products.

c. For any internal non-substantial component of non-homogeneous products.

d. For the product as a whole.

e. s1 = SMOGRA ≤ 30m2/s2and TSP600s≤ 50m2; s2 = SMOGRA ≤ 180m2/s2and TSP600s≤ 200m2; s3 = not s1 or s2.

f. d0 = no flaming droplets/particles in EN 13823 within 600s;

d1 = no flaming droplets/particles persisting longer than 10s in EN 13823 within 600s;

d2 = not d0 or d1.

Test Items, Method and Results:

2 RESULTS AND OBSERATIONS

|

Method |

Parameter |

Result |

|

| EN ISO 1716:2010 | PCS |

PVDF paint coating, MJ/m2 |

0.4367 |

|

Aluminum coil, MJ/kg |

0 |

||

|

Polymeric membrane film, MJ/m2 |

2.8746 |

||

|

A2 FR non-combustible mineral core, MJ/kg |

2.1111 |

||

|

Polymeric membrane film, MJ/m2 |

2.8746 |

||

|

Aluminum coil, MJ/kg |

0 |

||

|

Primer paint, MJ/m2 |

0.0895 |

||

|

The Whole Product, MJ/kg |

2.1347 |

||

|

EN 13823:2020+A1:2022 |

FIGRA0.2MJ, W/s |

0 |

|

| THR600s , MJ |

0.408 |

||

| LFS, m |

<Edge of specimen |

||

|

SMOGRA, m2/s2 |

0 |

||

| TSP600s, m2 |

16.2 |

||

| Flaming droplets/particles |

No flaming droplets/particles occur within 600s |

||

Note

1. Per EN 13823, the samples were free standing at a distance of 80mm from the backing board. Backing board was a 12mm thick calcium silicate board. The density of the calcium silicate board was 850kg/m3.

ΔThe information of each component of the product was declared by applicant, see below table.

|

Layer No. (from face to back) |

Material of each Layer |

Mass per unit area (kg/m2) |

Thickness (mm) |

|

1 |

PVDF paint coating |

0.030 |

0.027 |

|

2 |

Aluminum coil |

1.355 |

0.500 |

|

3 |

Polymeric membrane film |

0.064 |

0.070 |

|

4 |

A2 FR non-combustible mineral core |

5.500 |

2.900 |

|

5 |

Polymeric membrane film |

0.064 |

0.070 |

|

6 |

Aluminum coil |

1.355 |

0.500 |

|

7 |

Primer paint |

0.011 |

0.009 |

3 CLASSIFICATION

The classification has been carried out in accordance with EN 13501-1.

|

Fire behaviour |

|

Smoke production |

|

Flaming Droplets | ||

|

A2 |

- |

s |

1 |

- |

d |

0 |

Reaction to fire classification: A2 - s1, d0

Original Issue Date: 2025-10-23 Intertek Report No. 251014005SHF-001

Test Items, Method and Results:

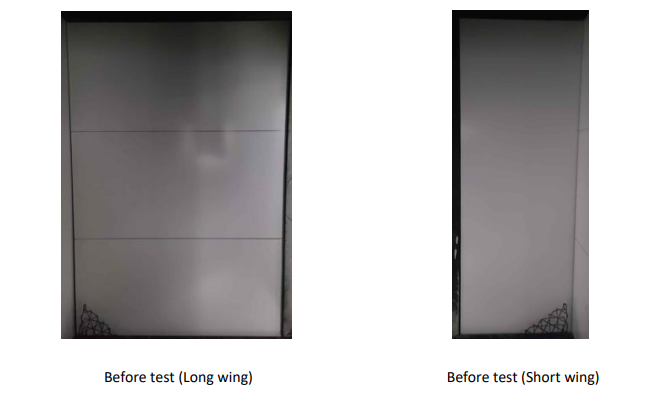

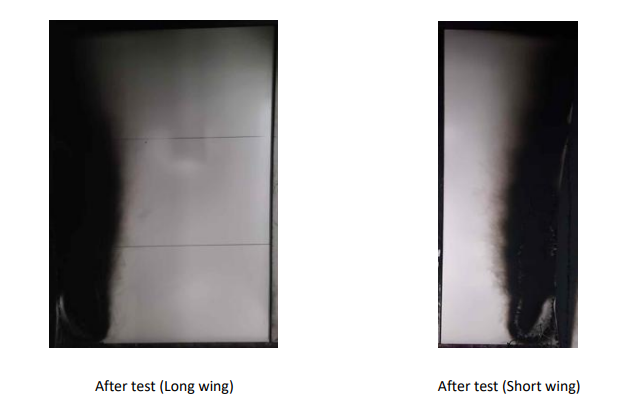

4 Test Photos of EN 13823

Original Issue Date: 2025-10-23 Intertek Report No. 251014005SHF-001

Revision:

|

NO. |

Date |

Changes |

|

250721002SHF-001 |

2025-10-23 |

First issue |