Highlights

Delta E (or ∆E) is a calculation of the change in color as measured in the Hunter Lab color space on a three-dimensional axes L a b. ACM finish warranties guarantee a color change of no more than Delta E5 over the length of the warranty, under defined terms and conditions.

Fluoropolymer paint systems, such as FEVE, PVDF provide exceptional color accuracy and resist color fade with warranties for 10, 20 or 30 years.

If you think about an ellipse containing all allowable color, any color has a sort of address, determined by the ratio of pairs of opposites. Simplistically, how much red or green it has, how much yellow or blue it has, or how light or dark it is. Colors whose addresses are closer together have a lower Delta E.

What is Delta E and why does it matter?

Delta E is the measured change of color from one color sample to another. Color matters. We use color to send a message or create a feeling. For corporations, colors represent a brand, acting as a part of the company identity as important as the name or logo. And when it matters most, close enough doesn’t cut it. Because visual perception can vary, color is defined in a 3D color space using a threepoint axes. Delta E represents the difference between a given color and a different color. There are two important reasons to measure color difference. First is color matching to ensure paint accuracy before it is applied to an ACM panels . The second is to determine the degree of change over time, often seen as fading, in order to verify the paint performed as expected after panel installation.

Small differences can have a great impact on the Delta E.

A lower Delta E means there has been less color shift.

A higher Delta E means a more significant color shift.

A Delta E of 1 may be perceptible by some with close inspection.

A Delta E of 5 may be noticible at a glance.

Invest in a paint system that lasts.

Understand that a small movement in the color reading can greatly impact where the color ends up. Fluoropolymers like FEVE and PVDF do the very best job of holding the original color for the longest time.

Finding the perfect color for your project or corporate identity is important. Keeping that carefully selected color looking it best for decades is also important. You deserve color accuracy and longevity. Your paint system should limit the fading of the color, often caused by UV exposure, toxic atmosphere, proximity to salt water and more.

We use Delta E to make sure our paint matches are accurate and to set limits on how much a color can change over the life of a finish warranty.

The industry standard for producing paint colors within a batch is Delta E 2 for a solid color and Delta E 2.5 for a color with a flake, such as Mica or Metallic.

Typical ACM finish warranties guarantee color changes no greater than Delta E 5 for the duration of the warranted period.

Your choice in paint and the pigment of that paint will determine how long the warranty period will be.

ALUSIGNPANEL Aluminum Composite Materials ( ACM ) factory have2 automated coating lines with a total monthly production capacity of 1,200 tons to sure the fast lead time and better for us control the ACM panels color difference within different batches .

Installation Tips :

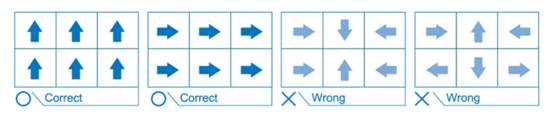

To avoid possible reflection differences (for metallic, special effect colors ), it is recommended to install the ACM panels in the same direction as marked on the protective film . Colour variations may occur between ACM panels originating from different production batches. To ensure colour consistency , the total requirement for a project should be placed in one order .